丨

EN

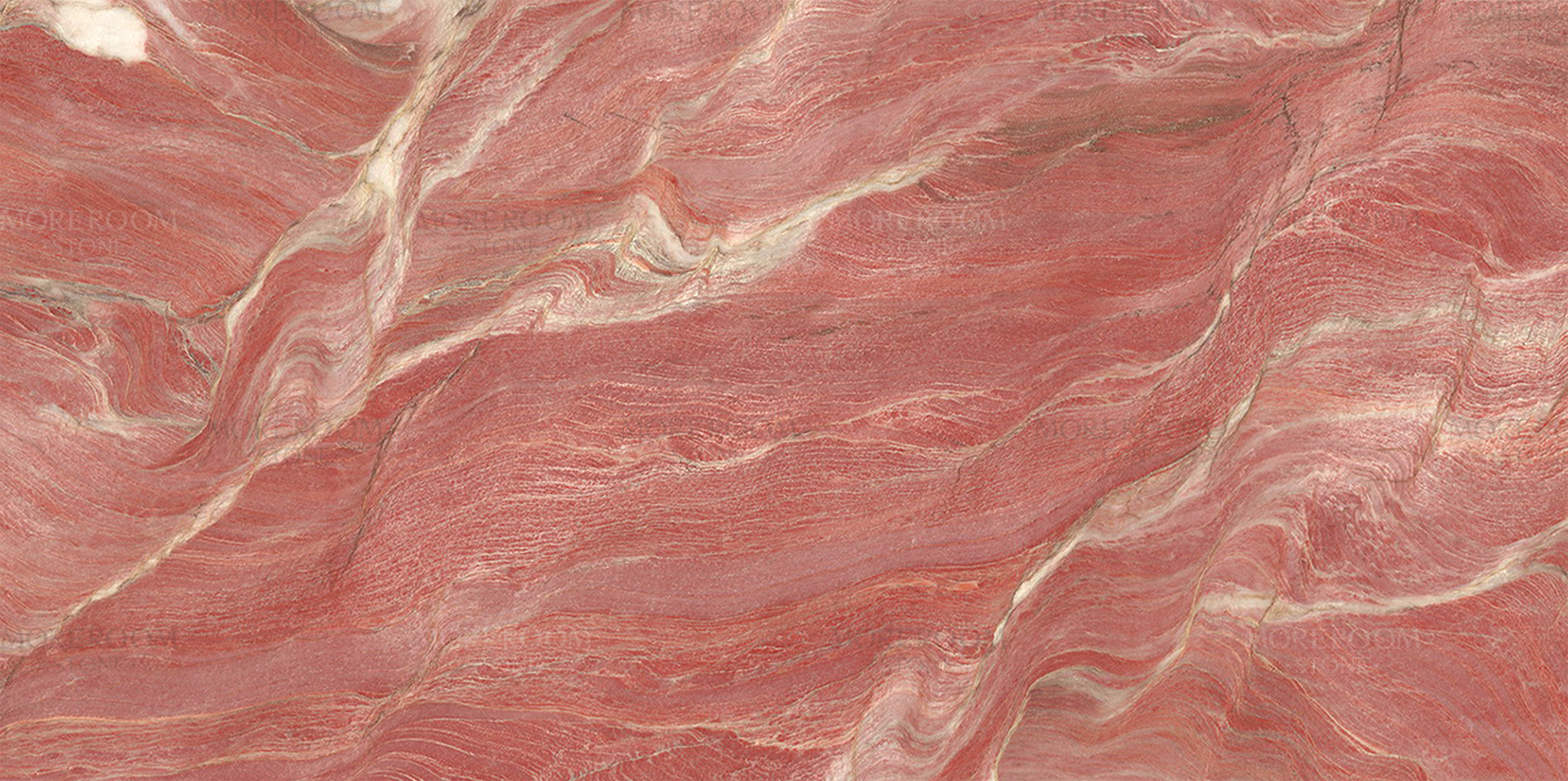

MOREROOM sintered stone manufacturer with more than 20 years of experience. With Italy and Spain teams to design high-end products. Focus on design, development, production and export from China to worldwide.

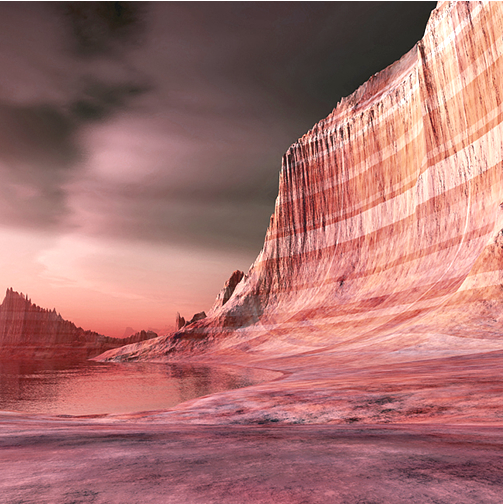

Drawing inspiration from natural marble, combined with industrial aesthetics and new materials, it is both atmospheric and full of tension, but also calm and durable, expressing the current natural and casual life attitude, and enjoying the high-end aesthetic design brought by rock slabs.

Design is not a skill, but the ability to feel and insight into the essence of things.

No outstanding work is completed in an instant and can not stand the test of time. Whether it is architecture or art, its most real value can only be judged by time.